Advanced Computer Vision in Manufacturing: Proven Methods for 2025

In today’s rapidly evolving industrial landscape, Computer Vision in Manufacturing has become an essential tool for ensuring Quality Control. As manufacturers face increasing pressure to streamline processes and enhance precision, the integration of computer vision technology in quality assurance is gaining momentum. This article delves into the transformative power of computer vision, highlighting its critical role in modern manufacturing. We’ll explore key applications, emerging trends, and real-world implementations to provide you with an in-depth understanding of how this technology is redefining the industry. Whether you’re an AI professional, a data science enthusiast, or a learner seeking deeper insights, this comprehensive guide will equip you with knowledge and inspiration to leverage computer vision in your projects.

Table of Contents

Benefits of Computer Vision in Manufacturing

Computer Vision offers substantial benefits in manufacturing, particularly in enhancing quality control. It enables the precise inspection of products, reducing defects and improving consistency. By automating visual inspections, manufacturers can achieve higher throughput while maintaining or even improving accuracy. Furthermore, it facilitates predictive maintenance by analyzing visual data to predict failures, minimizing downtime.

Another notable advantage is cost reduction. Automated systems reduce the need for manual inspections, thus lowering labor costs. Additionally, by identifying defects early in the production process, material waste is minimized, leading to significant savings.

Key Applications of Computer Vision

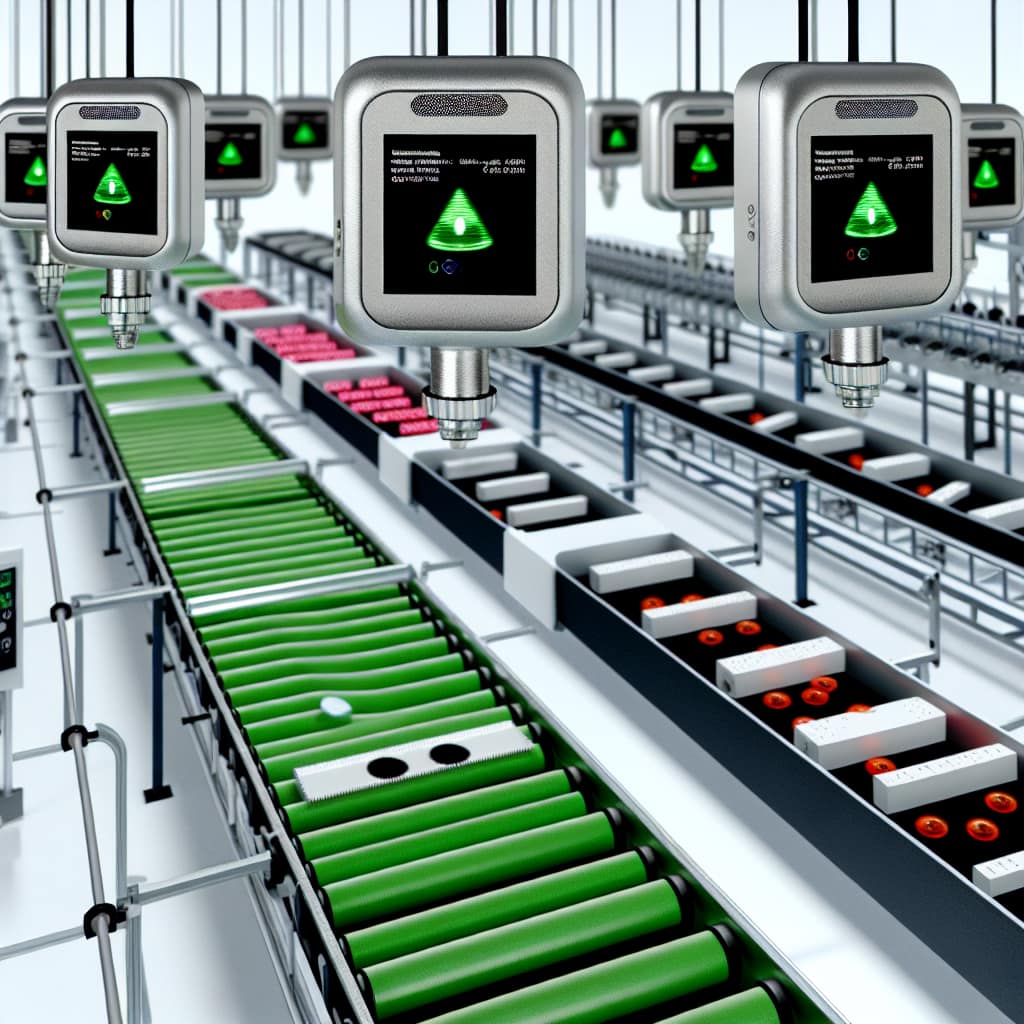

Inspection and Quality Assurance

One of the primary applications of computer vision in manufacturing is automated inspection. High-resolution cameras and sophisticated algorithms enable the detection of defects that are difficult to spot with the naked eye. From surface scratches to assembly errors, computer vision ensures that only products meeting quality standards progress through the production line.

Robotic Guidance and Automation

Computer vision is pivotal in guiding robotic arms for tasks such as assembly, packaging, and sorting. It enhances the precision of robots by providing real-time feedback, ensuring that they adapt to variations in product placement or orientation.

Process Optimization

By continuously monitoring production lines, computer vision systems gather valuable data. Analyzing this data helps identify bottlenecks and inefficiencies, enabling manufacturers to refine processes and enhance productivity.

Advanced Frameworks and Tools

Leading frameworks such as TensorFlow and OpenCV are extensively used in implementing computer vision in manufacturing. TensorFlow’s robust machine learning capabilities allow for the development of sophisticated models for defect detection, while OpenCV provides a comprehensive library of functions for image processing.

Emerging tools like PyTorch are also gaining traction due to their dynamic computation graph and ease of use. These frameworks, coupled with advancements in AI hardware, such as NVIDIA GPUs, empower engineers to deploy high-performance vision systems.

Real-World Examples

One significant example of computer vision in action is at Tesla’s manufacturing plants, where it plays a critical role in the quality control of vehicle assembly. High-resolution cameras assess the alignment of car panels and paintwork quality, ensuring every vehicle meets stringent quality standards.

Similarly, Siemens utilizes computer vision to inspect bottle caps in their manufacturing facilities. The system accurately detects defects, preventing defective products from reaching consumers and enhancing overall production efficiency.

Emerging Trends in 2025

As we look towards 2025, the integration of AI with computer vision in manufacturing is expected to deepen. Innovations such as edge computing will enable faster processing and analysis of visual data directly on the shop floor. This trend will be crucial for real-time quality assurance in high-speed production environments.

Moreover, the adoption of augmented reality (AR) combined with computer vision is on the rise. This combination will provide factory workers with enhanced visualization tools for training and maintenance, leading to improved operational efficiency.

Researchers are also exploring the potential of quantum computing to exponentially increase the processing power available for complex visual tasks, setting the stage for groundbreaking advancements in the field.

Frequently Asked Questions

What industries benefit most from computer vision in manufacturing?

Computer vision is beneficial in industries such as automotive, electronics, and pharmaceuticals, where high precision and quality control are vital.

How does computer vision improve quality control?

It enhances quality control by automating visual inspections, reducing human error, and enabling the detection of minor defects swiftly.

Are there any challenges in implementing computer vision?

Challenges include the high initial setup cost, the complexity of system integration, and the need for skilled personnel to manage the technology.

Can small manufacturers afford computer vision technology?

Yes, with the advent of more affordable solutions and scalable systems, small manufacturers can also implement computer vision to enhance their operations.

Conclusion

In summary, computer vision is revolutionizing the manufacturing industry by elevating the standards of quality control through automation and precision. As technology advances, its applications will continue to expand, offering even greater efficiency and cost savings. For AI and data science professionals, staying abreast of these trends is crucial to leveraging new opportunities within the sector.

To remain informed and keep up with the latest in AI and Computer Vision, subscribe to our newsletter and explore our other articles on emerging technologies and trends.